Data

This section contains and illustrates the data taken from the fully functional AC hat. The data provided is the measured temperature and pressure differences along with the simulated data.

Resulting System Cooling

The results of the project demonstrate that there is a significant temperature gradient between the outlet of the compressor (T1) and the inlet of the evaporator after the expansion valve (T3). Depressurization after the expansion valve allows the evaporator to transfer heat into the refrigerant, creating an endothermic reaction that cools the pipes as the refrigerant evaporates. Calculating the coefficient of performance (COP) results in an average performance of 1.1. This indicates that the evaporator is releasing more heat out from the brim of the hat than is put through the compressor, a positive outcome for future designs for this project. Moving forward with this project, it is important to design around the heat dissipated out of the evaporator. It is clear with these results that more work is needed on the evaporator coils in order to increase the coefficient of performance.

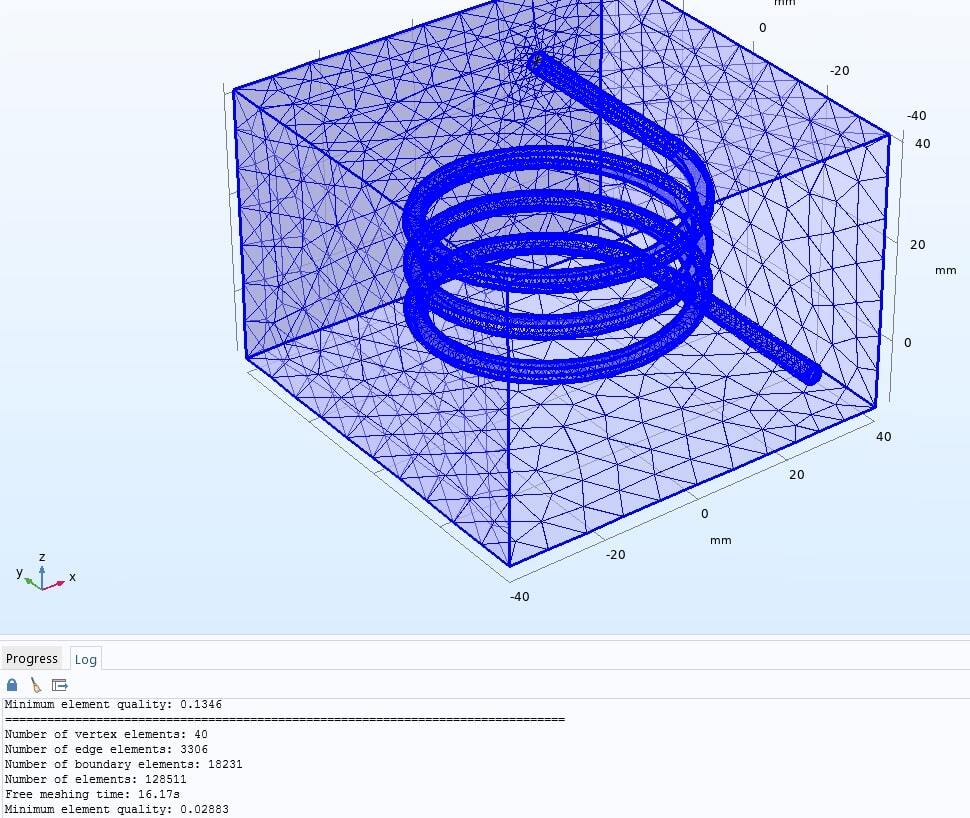

Heat Dissipation Engineering Calculations

The Cerebro project is a closed system, which ment that not data could be collected about the system until the hat was completed and charged. Because of this the team had to rely on deriving equations that modeled the system in order to ensure that components would be adequate in the system. One example of this was modeling the total heat dissipation from the condenser on the top of the hat. A Matlab script was written based off the determined equations, which then provided a heat dissipation estimation before the system manufacturing was completed.