Problem

This section takes an indepth look into what problems the Cerebro hat solves, and the scope of this project.

Project Introduction

Background

Construction sites are commonly located in extreme environmental conditions, such as excessive heat during the summer months. This is known to lead to heat stroke for those working for long durations in these areas. Extreme heat is only made worse with solid plastic hats trapping heat around the head. To assist in preventing heatstroke and to keep these workers comfortable on a worksite, a personal portable cooling system would be a welcomed relief. Team 609 Cerebro is working toward the solution to this problem: an air-conditioned hardhat. The hat’s air-conditioning will encompass the full vapor compression cycle, consisting of a compressor, condenser, capillary tubes working as a thermal expansion valve, and an evaporator. The Cerebro hardhat will bring an additional safety feature to the user by providing cooling for protection against heat stroke to improve the comfort of construction workers in hot environments.

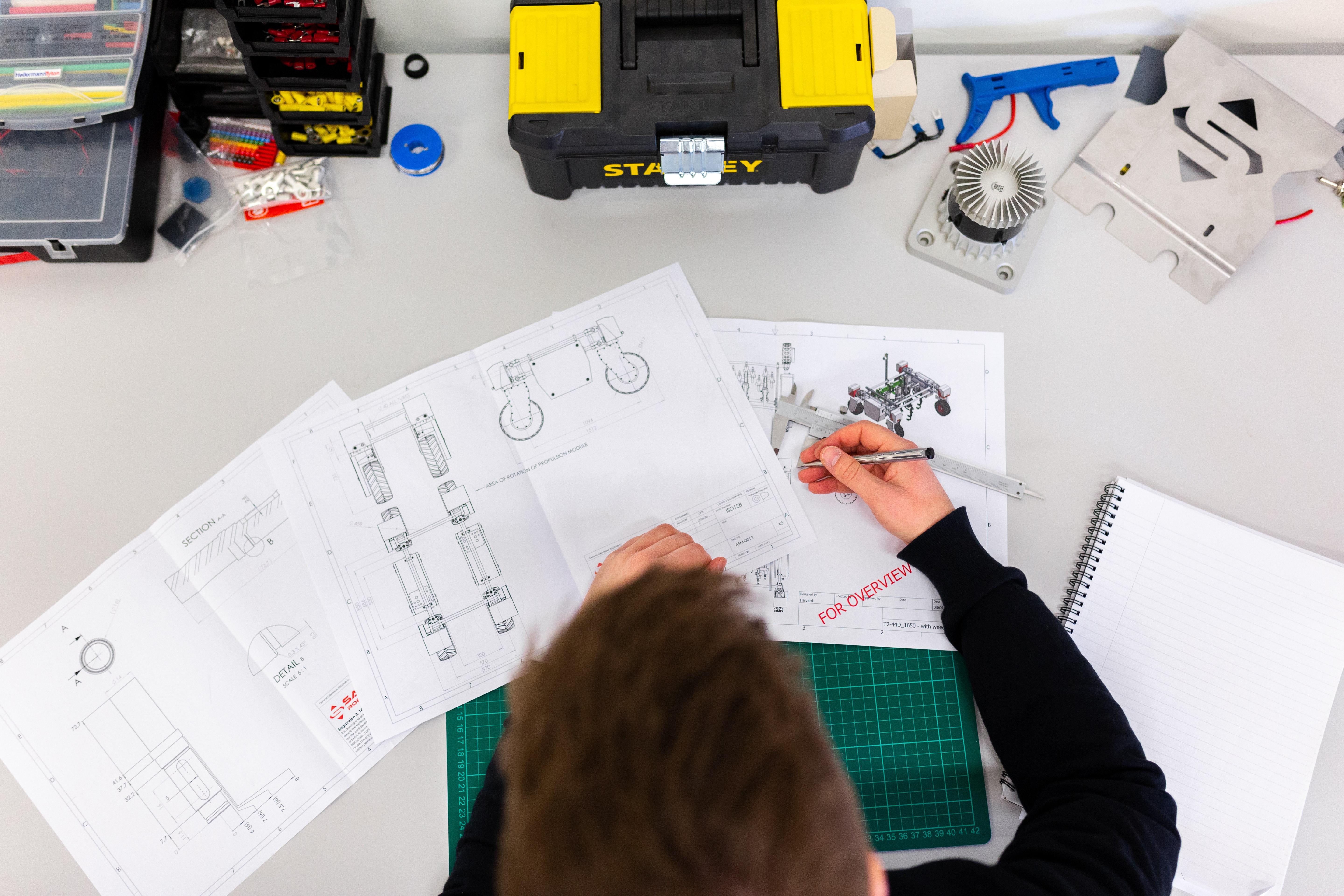

This is a new project to Oregon State University, therefore, the team started from the very beginning with just the concept. The team started with weekly concept design iterations for various layouts and components of the hat. Once the three concept generation phases were over, the team researched the plausible ideas further and began to ideate the layout of the hat while making a representative model of the hat. This is where the team left off last term. From there, the team began to manufacture different components of the hat such as the evaporator with aluminum egg carton and copper piping, the condenser, and the capillary tube. Following this, the team began working on the assembly of the entire system. This included electrical wiring of the system, fan placement, battery life, and system plumbing. Some of these components and subsystems were altered for the sake of progressing the project as far as possible before the end of the course. These changes will be discussed throughout the document. In the initial setup of the hat, the fans were going to be connected directly to the power source; however, upon further research, the team determined that the compressor driveboard fan pins would suffice to power all the fans. Originally, the evaporator fans were going to be placed underneath the evaporator itself, but to allow the user to have more field of view, they are now on top of the hat’s brim with holes cut into the brim of the hat for better airflow. The engineering specification pertaining to a long battery life was changed from two hours to one hour because the system pulls around 19 Amps, but the most cost effective and realistic battery the team could find that fit the system’s specifications was a 24 V 20 Ah battery. Therefore, the system will only be able to run for about an hour, which was approved by the project sponsor. Lastly, the plumbing of the hat that holds the refrigerant was originally designed to have compression fittings joining the pipes; however, to limit the amount of potential leaks in the system, the team plans to braze the pipes in all feasible locations. Overall, the team has kept the main design of the hat the same, however, some components and subsystems have been altered to assist the team in completing the project before the end of the course. These changes will be discussed throughout the document.

Project Scope

The scope of Project CEREBRO encompasses the reconfiguration of the traditional, Occupational Safety and Health Administration (OSHA) compliant hardhat into a cooling device. This device relies on the vapor-compression refrigeration cycle in order to provide long-lasting relief to the user working in a potentially high heat-stress environment. Vapor compression has long been used for refrigerators and industrial cooling applications. With each passing year, smaller and smaller designs have been shown to be feasible, and only recently has there been the possibility to make such a system portable. Some existing cooling hardhats use phase change material cold packs to cool the hat, such as the company Air2O’s hardhats [1]. The team recognized the limitations with such a design: limited battery life, small cooling capacity, and the unsustainable nature of their cooling system. The Cerebro hardhat will have higher cooling capabilities than existing cooling clothing due to the onboard vapor compression air conditioning unit; and based on the team’s research, a portable vapor compression cycle that is built into clothing has never been made.

Using a pre-selected small vertical Aspen compressor, the team has designed, modeled, and manufactured a refrigeration cycle that is able to fit on the top, interior, and sides of a standard hard hat. The vapor-state refrigerant will be taken in by the compressor from the cycle, compressed, ran through a condenser to dissipate heat, depressurized to be extremely cold, and finally used to cool ambient air which is then administered to the worker’s head and down their body. The team had to balance the needs of the consumer and sponsor, keeping in mind the health hazards a heavier hard hat may produce. The goal of this project was to decrease skin temperature by 15°C from ambient. Due to the short timeframe of the project, and the projects sponsors desire to have a vapor compression cycle running on a hat no matter the weight or shape; the team had to make many decisions that put certain requirements on hold over getting the system operational.